Manufacturing ERP Software – Is It a Wise Choice For a Small Company?

The use of enterprise resource planning (ERP) software in the manufacturing industry is becoming increasingly popular as manufacturers seek to streamline their processes and improve efficiency. While ERP software offers a wide range of advantages, there are many pitfalls that businesses must be aware of before investing in an ERP system. This article explores vital points when selecting and implementing an ERP software solution for a manufacturing business.

ERP system – definition

An Enterprise Resource Planning (ERP) system is a vital tool for businesses, enabling them to manage and streamline their operations. ERP systems are built to integrate a company’s different departments and functions, such as finance, manufacturing, sales, inventory management and customer service. By consolidating multiple systems into one software package, an ERP system simplifies data sharing across the organisation while reducing operational costs. But there is a question: do you need an all-in-one production ERP system for your small business? Because it could be better than it sounds.

Unfortunately, many pitfalls are associated with using an ERP system in the manufacturing industry. Deploying an ERP system involves considerable time and money investments which can be difficult for small or medium-sized businesses to afford. Additionally, implementing an ERP solution requires specialised technical knowledge, which may be lacking in some companies. Finally, changes in technology or business processes may require costly upgrades or modifications that could affect the system’s performance over time.

Manufacturing ERP Software Benefits

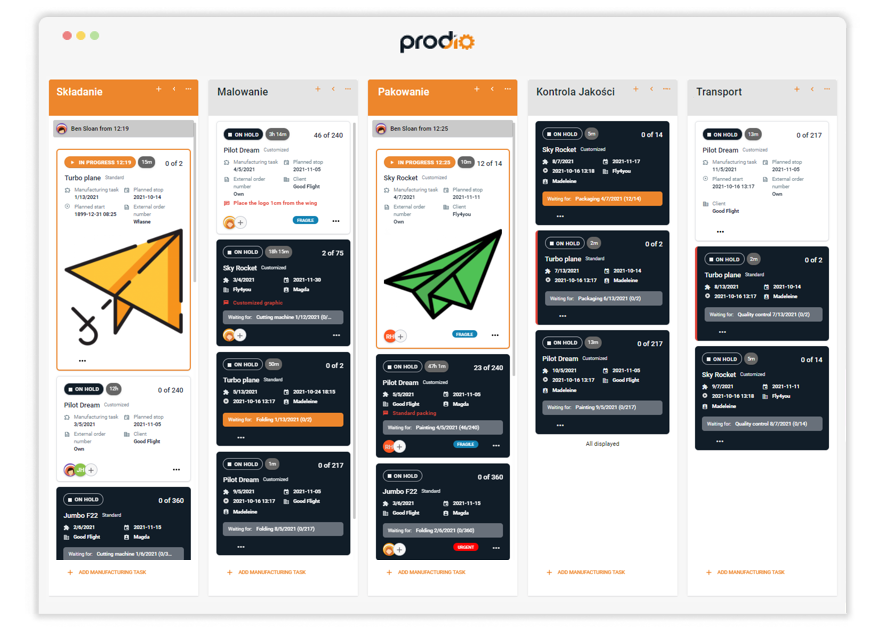

Manufacturing ERP software can offer many benefits to businesses in the manufacturing industry, but it is also essential to be aware of potential pitfalls. ERP software can be an excellent solution for companies looking to increase efficiency, automate processes, and streamline data management. In addition, it can help manufacturers coordinate activities across departments, improve communication between all levels of the organisation and ultimately boost productivity.

By using an integrated system for data management, manufacturers can access real-time information on the production process and performance. This enables them to make better decisions quickly and accurately, leading to increased profit margins. Additionally, some Manufacturing ERP solutions integrate with other business applications, such as accounting or customer relationship systems allowing organisations easy access to related data from multiple sources in one location.

ERP system drawbacks: complex setup

Manufacturing ERP software can be a valuable tool, but there are drawbacks to consider before investing. One of the most significant drawbacks is the complex setup required to get started with a manufacturing ERP system. This complexity can involve time and resources that some companies may have yet to be available.

One issue related to the complexity of setup is that it often requires specialised personnel who understand the intricacies of setting up an ERP system. Therefore, companies must ensure they have staff proficient in technology and understand how an ERP system works, or they’ll need to hire IT professionals to help them with the setup process. Additionally, there may be hardware requirements, such as servers and other components, that need configuring.

Cost Considerations: Upfront and Maintenance

Manufacturing ERP software can be an excellent choice for businesses looking to streamline operations, but before taking the plunge, it’s essential to consider the associated costs. Upfront and maintenance costs are two of the most significant areas to consider when evaluating which software solution is best for your small business.

Be prepared for the very high costs of implementation. First, you will have to double the price from the original vendor’s offer. Sometimes there are so-called “free ERP programs”, but they are generally low-end marketing strategies. In many cases, only the base module license is free, allowing companies to make big bucks on implementation services because you purchase their product without technical support.

Investing in an ERP system requires some upfront investment. Depending on how advanced you need the system to be, this could range from a few hundred dollars up to thousands of dollars. Any customisation or add-on purchases will also require an additional financial commitment. When budgeting for Manufacturing ERP software, it’s important to include all of these components so you can accurately calculate the total cost of ownership (TCO).

Security Risks: vulnerable data

Data security is always a primary concern for any organisation. Still, it is significant for small companies that may need more resources or expertise than larger enterprises in protecting sensitive information. In addition, ERP systems often house large amounts of confidential data, making them especially vulnerable if not secured properly. Therefore, steps must be taken to ensure that any system implemented will protect customer details, financial information and other critical records from unauthorised access or malicious attacks by hackers.

User Training: learning curve

User training is essential when selecting manufacturing ERP software for a small company. Proper personnel training on the new system will ensure a smooth transition and help the organisation realise its full potential. In addition, by understanding the basic concepts of ERP systems, users can quickly and efficiently learn how to use the software and take advantage of all its features.

At first glance, ERP systems can seem overwhelming for a small business with limited resources or personnel. That’s why companies charge additional training fees. Also, the whole process is lengthy because navigation through various ERP components can be tricky.

Conclusion: Evaluate Carefully

In conclusion, the choice of manufacturing ERP software for a small company should be taken seriously. Companies must evaluate their current business needs and objectives carefully before selecting an ERP system to ensure that it meets their requirements. Additionally, companies should examine the features of each system to gain a complete understanding of its capabilities and shortcomings to make an informed decision.

There are many factors to consider when determining whether or not manufacturing ERP software is a wise choice for a small company. It is crucial to take into account the amount of capital required upfront as well as the potential return on investment over time. Companies must also factor in the cost of training staff on new systems and any technical support they may require during implementation and beyond. By carefully evaluating all aspects involved, business owners can decide which type of software best suits their operations.

Personal contact info – slikgepotenuz@gmail.com

Permanent Address :- Montville, NJ

CEO and co-founder at Cloudsmallbusinessservice.com